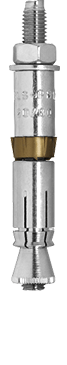

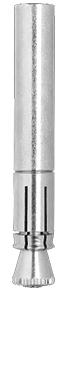

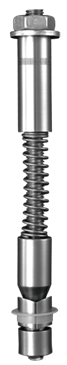

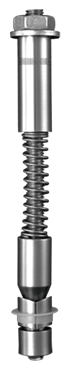

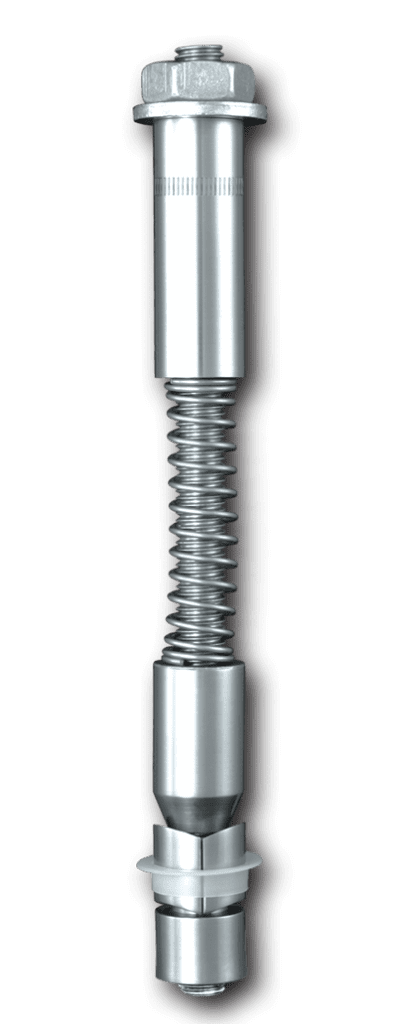

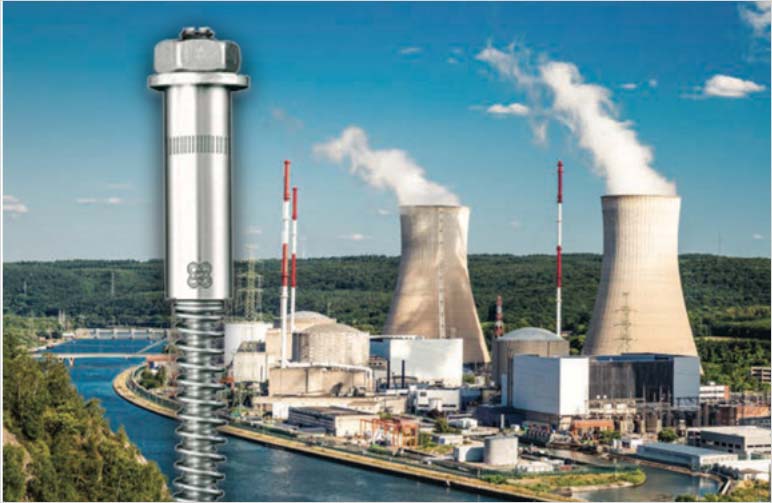

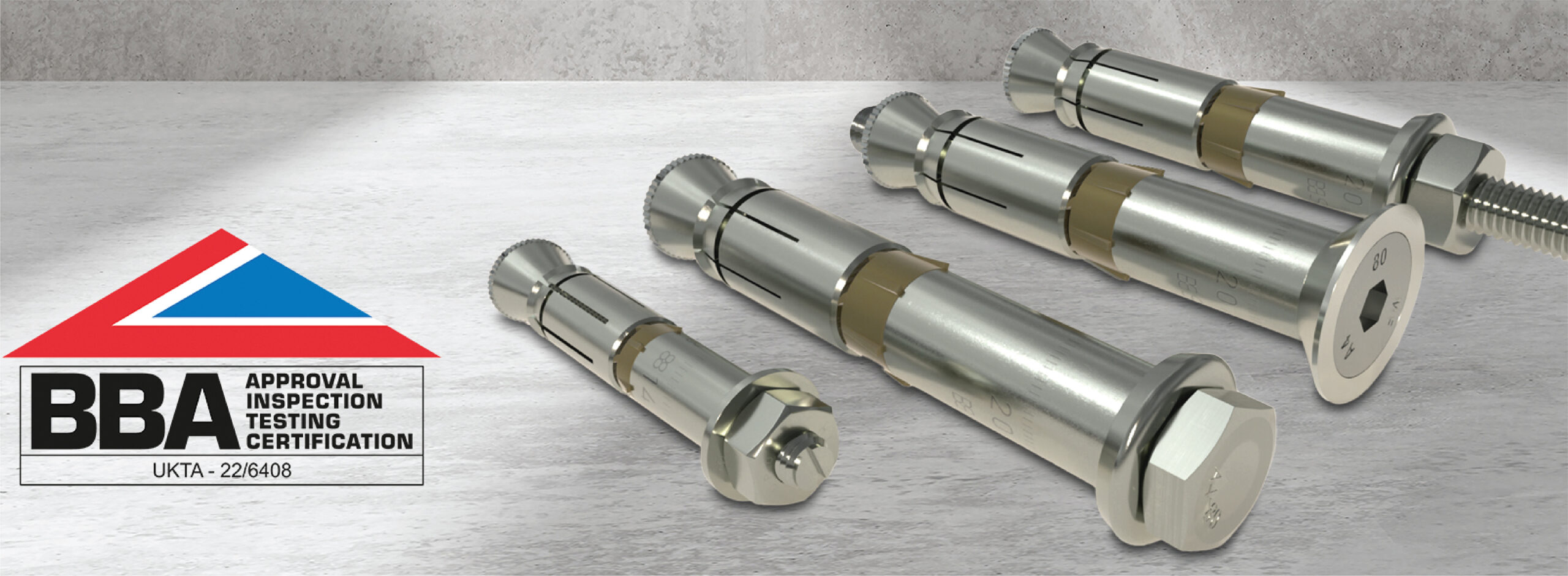

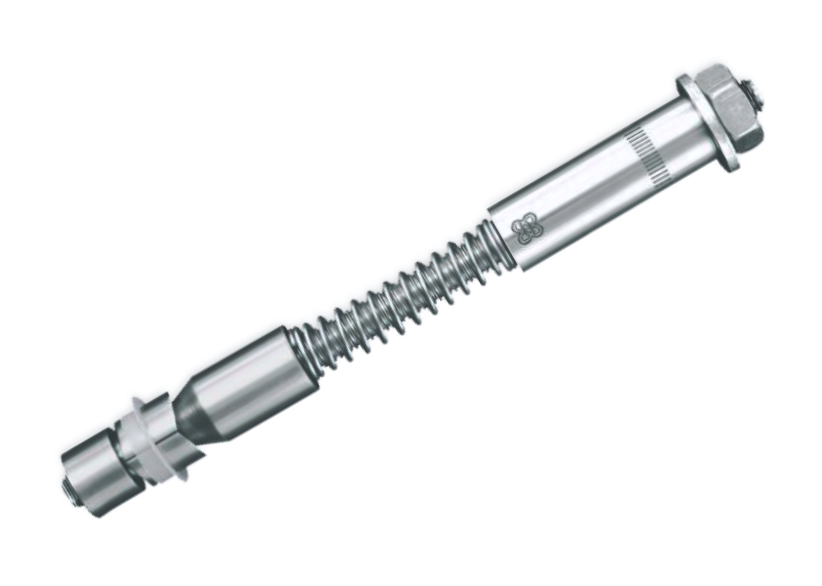

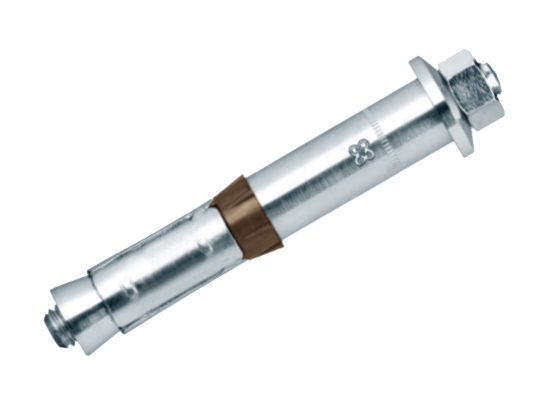

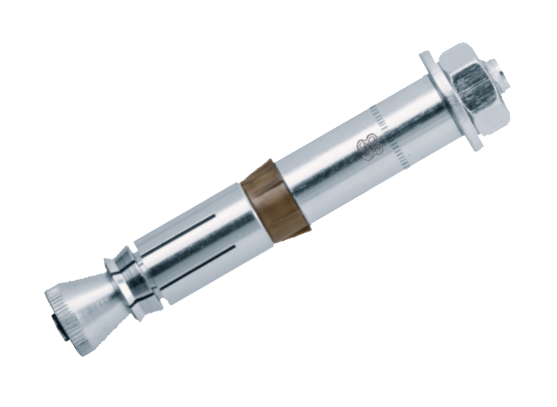

THE LIEBIG® ANCHORING RANGE OFFERS GLOBAL RECOGNITION AND TOTAL RELIABILITY FOR EXCEPTIONALLY HIGH LOADS IN BOTH CRACKED AND NON-CRACKED CONCRETE

LIEBIG® Anchoring Technology…

NOW WITH EJOT® GLOBAL SUPPORT

The combination of EJOT’s technical expertise and LIEBIG’s technical innovation provides a fit that will ensure that the world’s finest anchoring technology is readily available with the necessary support and guidance. Placing LIEBIG anchoring technology back in the hands of the engineer and contractor alike.

LEARN MORE

Latest News.