Option 1 & Option 7 LIEBIG Anchor Technology

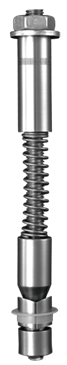

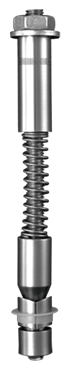

Option one and option seven are two types of ETA-approved undercut anchors, a special kind of anchor installed into concrete and brick that is proven to be one of the strongest on the market for supporting structures such as steel columns and tunnels. For this reason, engineers often use these anchors for high-load projects in power plants, nuclear facilities and theme parks, where the consequences of structural failure could be catastrophic.

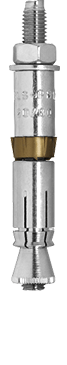

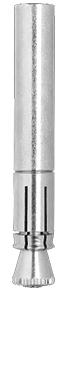

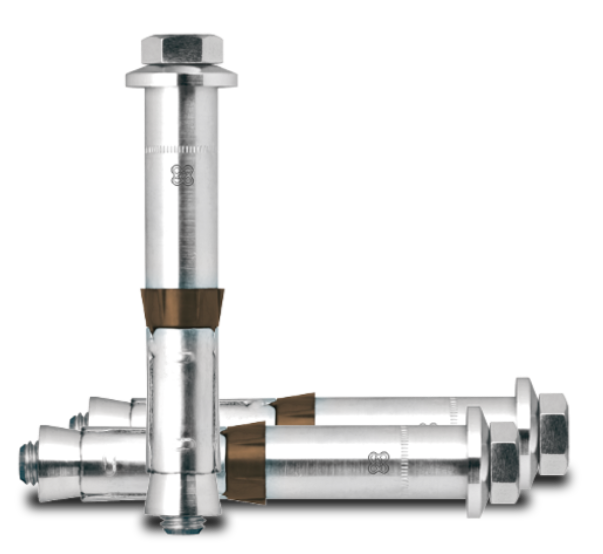

To install an anchor bolt, a hole of specific depth and diameter must first be drilled into the concrete member. After clearing the hole of dust and debris, an undercut is created using a special drill that can bore a notched opening to accommodate the bolt’s expanding segments, which can then be driven into the hole and expanded to form the undercut connection. Also known as the positive mechanical interlock, this mechanism relies on the compressive strength of the member to balance the application’s static and dynamic loads.

Option-One: For Cracked and Non-Cracked Concrete

ETA Option 1 undercut anchors are approved for cracked and non-cracked concrete, including in floors, ceilings and walls. This is the strongest type of undercut anchor available out of the twelve options that have been granted a European Technical Assessment (ETA) marking, which is a technical standard used to detail and verify the performance of construction products.

As option 1 can be used for cracked and non-cracked concrete, this means that it is able to safely support applications in areas most vulnerable to cracking, otherwise known as the tension zone. As the name suggests, this is where a concrete member experiences the most stress under load and, as a result, will be the most likely location for cracking to appear. While cracking is a sign of fatigue, the reliability of this setup means that the steel anchor will likely fail before the concrete, allowing engineers to better anticipate outcomes because steel failure is more predictable than concrete failure.

Option Seven: A Versatile Undercut Anchor

Option 7 is part of a class of undercut anchors (options 7-12) that is ETA-approved for non-cracked concrete applications. While not suitable for tension zones on concrete members, this option is very versatile for concretes with a strength class over 20/25. Anchors are often required in many different locations on a concrete member, and sometimes in close quarters with other anchors.

For this reason, option 7 undercut anchors are very useful. They have been tested under load and approved for areas where space is limited and the edge distances are small, making them ideal for bolting awkward attachments.

Advantages of Using Undercut Anchors

– The positive mechanical interlock mechanism ensures that fixtures remain secure, even under dynamic loads.

– Undercut anchors are made from highly durable, strong materials that go beyond the minimum safety requirements.

– This reliability is matched by the range of options available for cracked and non-cracked concrete scenarios.

– They are ideal for tight spots where the anchor spacing and edge proximity is tight.

European Technical Assessment

As previously mentioned, the European Technical Assessment is the standard-bearer for ensuring that an anchor is safe to use for certain applications and materials and, therefore, this should be considered when sourcing undercut anchors.